Technology in high power converters

Modern power electronics plays important role in motor control for not only transportation and also other combustion driven equipment. Wide bandgap semiconductors such as SiC and GAN devices enable us to develop high performance converters. Our focus is on DC/AC inverters with 800V DC voltage for power range of 5 – 500 kW. The general objective is to achieve high efficiency and high power density. These inverters can be operated in 1-30 kHz switching frequency in motor drives for vehicle applications and quadratic load applications such as marine propulsion and heavy-duty cooling fans.

- Three-phase inverter: power up to 250 kW, efficiency up to 99 %;

- Double three-phase inverter with shared DC links and housing: power up to 500 kW.

Wide band-gap (WBG) semiconductors

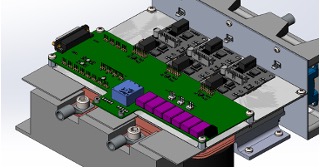

We have built our inverters with WBG devices, specially 1200V SiC chips and power modules from the top semiconductor producers. The voltage level matches the requirements of heavy-duty vehicles and equipment we want to electrify. These devices combined with other technologies give us freedom to design high-power inverters in small size. The higher speed switches enable much faster energy conversion cycles, which is crucial in some demanding systems like high power wireless charging and high power drives.

Advanced DC-link

With use of modern SiC power modules, DC capacitors of the DC-link become a dominant part in an high power inverter. Size reduction of these capacitors is actual challenge for compactness of the whole inverter. Our solution can significantly reduce the size of these capacitors and extend the life time. Another critical component of a DC-link is the DC busbars which is contributor to stray inductance and over shooting in switching phase. Our busbars is designed for minimum stray flux and thermally well managed.

Adaptive control

To reduce the losses and keep long lifetime, adaptive control method is developed to control the commutation of the semiconductors and internal settings dynamically. Optimisation is not only in design phase but also in operation phase. It is specially important for commercial drivetrains. Balance between output performance and component degradation is kept according a predefined strategy. Long life-time of expensive equipment contributes to high ownership value and societial sustainability.